19th April 2021

- Hannah G

- May 4, 2021

- 3 min read

Updated: May 24, 2021

Research

Japonsime was happening at the time the blouse I’m analysing was made, this term refers to the rise in popularity of combining Japanese and western design. The symmetrical design and linear pleats of the blouse reflect this as symmetry and linear lines are features of Japanese design. This link to japan remined me of my previous project where I created a jacket inspired by the kimono. The kimono is made from a large piece of fabric that wraps around the body, so its construction creates little waste. I’m interested in this idea of manipulating the fabric using smocking, rather than cutting out pattern pieces and creating lots of waste. This is a method that could be used more in contemporary fashion to help with moving towards a more sustainable industry. Another example of how the kimono is great to look at for sustainability is because it is made from a large piece of fabric. Therefore, making it easier to turn into another garment than garments with lots of pieces. I’m trying to develop this idea in my project by creating the silhouette with smocking rather that cutting seams or darts. This means that the fabric could possibly be reused in the future and turned into something or smocked in a different way. Zero waste pattern cutting is another method of pattern cutting by creating little to no waste, that I could research further.

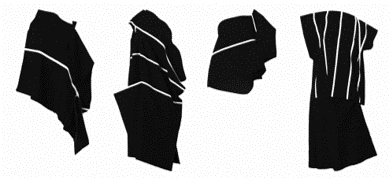

The Japanese culture is also very good at maintaining tradition but moving forward with innovation in technology. Issey Miyake is one brand which reflects this idea as they combine traditional Japanese design such as garments made from a piece of cloth, with 3D CAD technology. 3D CAD such as CLO 3D reduce the need to make lots of physical samples which take time and use a lot of fabric which contributes to waste and lack of efficiency. Creating garments on CLO 3D means you can pattern cut, view different fabrics/colours easily and try it on a 3D model. This means it’s easier and quicker to improve the garments design and fit. This program could also be used to show a client/customer what the final garment will look like without physically making it, allowing any alterations to be done easily. I’ve been trying to teach myself how to use the program but its complicated. That is one downside of CLO 3D. But I hope that I can make trial out simple shapes and garments eventually as part of my project.

CAD LECTRA is another technology which could play a role in sustainability, as once you understand how the program works you can create patterns quicker than manual. It also prevents the need for using up pattern paper and fabric addressing the issue of waste. For my project I’m going to use LECTRA to grade my pattern, this is a lot quicker and easier that doing it manually. I may also use it to create a simpler more affordable version of my final garment, you can double check that seams match and alter patterns simply. The pattern can then be sent along with tech packs etc. digitally to factories for production. One thing a miss with creating patterns on LECTRA is experimenting with drape on the stand, as a designer I enjoy doing this and it can lead to new and interesting silhouettes. You also need to have great knowledge of pattern cutting to use it.

Comments